3d printer filament guide

3d printer filament guide

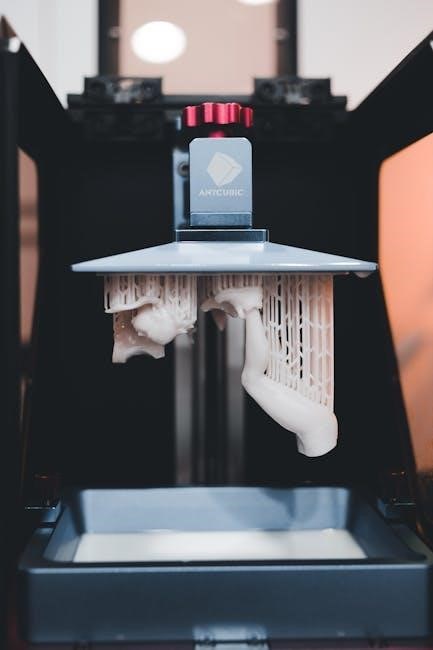

3D printer filaments are essential materials used to create objects layer by layer․ They come in various types, each offering unique properties like durability, flexibility, and heat resistance․ Choosing the right filament ensures high-quality prints tailored to specific needs, whether for prototypes, tools, or artistic designs․ Understanding filament types and their optimal settings is crucial for achieving consistent and successful 3D printing results․

1․1 What Are 3D Printing Filaments?

3D printing filaments are materials used in Fused Deposition Modeling (FDM) printers to create objects layer by layer․ They are thermoplastic polymers extruded through a heated nozzle․ Common types include PLA, ABS, PETG, and TPU, each offering unique properties like strength, flexibility, and heat resistance․ PLA is biodegradable and easy to print with, while ABS is durable but requires higher temperatures․ PETG balances strength and flexibility, and TPU is ideal for flexible applications․ Filaments come in various colors and diameters, with 1․75mm being the most common․ Proper filament selection ensures successful prints tailored to specific needs and applications․

1․2 Importance of Choosing the Right Filament

Choosing the right filament is crucial for achieving optimal 3D printing results․ Filaments vary in material properties, affecting durability, flexibility, and heat resistance․ Using the wrong type can lead to poor print quality, warping, or structural weakness․ Matching the filament to the intended application ensures functionality and longevity․ For example, outdoor items may require UV-resistant materials, while mechanical parts need high-strength options․ Budget and environmental considerations also play a role, as some filaments are more cost-effective or biodegradable․ Selecting the appropriate filament ensures compatibility with your printer and delivers the desired performance for your projects․

Types of 3D Printing Filaments

3D printing filaments include PLA, ABS, PETG, and TPU, each offering unique properties like durability, flexibility, and heat resistance, catering to diverse printing needs and applications․

2․1 PLA (Polylactic Acid)

PLA (Polylactic Acid) is a biodegradable and plant-based filament, making it eco-friendly and odorless during printing․ It is known for its low warping and high layer adhesion, producing smooth finishes․ PLA is ideal for beginners and detailed prints, as it works well at lower temperatures without requiring a heated bed․ However, it is brittle and less durable, making it unsuitable for outdoor or high-stress applications․ PLA is a popular choice for prototypes, decorative items, and models due to its ease of use and consistent results․

2․2 ABS (Acrylonitrile Butadiene Styrene)

ABS (Acrylonitrile Butadiene Styrene) is a strong, durable, and impact-resistant filament, ideal for functional parts and outdoor applications․ It requires higher temperatures for printing and benefits from a heated bed to prevent warping․ ABS is commonly used for automotive parts, tools, and household items due to its strength and heat tolerance․ However, it emits fumes during printing and can be challenging for beginners due to its sensitivity to temperature and humidity․ Proper ventilation and a stable printing environment are essential for successful ABS prints, making it a popular choice for experienced users needing robust, long-lasting results․

2․3 PETG (Polyethylene Terephthalate Glycol)

PETG (Polyethylene Terephthalate Glycol) is a versatile and widely used filament, known for its strength, flexibility, and resistance to warping․ It combines the durability of ABS with the ease of printing of PLA, making it ideal for mechanical parts, outdoor applications, and prototypes․ PETG is odorless during printing and offers good layer adhesion, reducing the need for a heated chamber․ It is resistant to UV light and moisture, making it suitable for outdoor use․ Printing PETG typically requires a temperature of 230-250°C and a clean, properly prepared build plate for optimal adhesion․ Its balance of performance and ease of use makes it a popular choice for both beginners and experienced users․

2․4 TPU (Thermoplastic Polyurethane)

TPU (Thermoplastic Polyurethane) is a flexible and highly durable filament, ideal for applications requiring elasticity and impact resistance․ It is commonly used for creating wearable items, flexible prototypes, and components like belts or hinges․ TPU is abrasion-resistant and maintains its shape under stress, making it perfect for functional parts․ Printing TPU requires a direct drive extruder and lower printing speeds due to its flexibility․ It typically prints at temperatures between 200-220°C and may need a heated bed for proper adhesion․ TPU’s flexibility and strength make it a valuable material for projects needing both durability and pliability․

Selecting the Right Filament for Your Needs

Selecting the right filament ensures your prints meet performance and aesthetic goals․ Consider factors like intended use, printer compatibility, and budget to make an informed choice․ Proper storage and handling also optimize filament performance, preventing degradation and ensuring consistent results․ By understanding filament properties and printer settings, you can achieve high-quality prints tailored to your specific needs․ Always check compatibility with your printer model and adjust settings accordingly for the best outcomes․

3․1 Factors to Consider: Intended Use, Printer Compatibility, and Budget

When selecting a filament, consider the intended use to determine required properties like strength or flexibility․ Printer compatibility is crucial, as not all filaments work with every printer model․ Budget also plays a role, as filaments vary widely in price․ High-end materials like TPU may offer superior durability but cost more․ Balancing these factors ensures you choose a filament that meets your project needs without exceeding your budget․ Always check compatibility with your printer’s specifications to avoid potential issues during printing․ A well-informed decision leads to better print quality and efficiency․

3․2 How to Store Filaments for Optimal Performance

To maintain filament quality, store them in a cool, dry place away from direct sunlight and moisture․ Use airtight containers or vacuum-sealed bags with desiccants to absorb humidity․ Filaments like PVA and Nylon are particularly sensitive to moisture, so proper storage is essential to prevent degradation․ Keep filaments away from heat sources and ensure the storage area is temperature-stable․ Avoid exposing filaments to humidity, as this can lead to brittleness or poor print quality․ Always handle filaments gently to prevent tangles or damage․ Proper storage ensures consistent performance and extends the lifespan of your filaments․

Settings and Configuration for Different Filaments

Adjusting temperature, speed, and layer height ensures optimal printing․ Filaments like PLA, PETG, and TPU require specific settings to achieve precise results and prevent issues like warping or adhesion failures․

4․1 Temperature Settings for Various Filaments

Temperature settings are critical for successful 3D printing․ PLA typically requires nozzle temperatures between 190°C to 220°C, while PETG needs slightly higher, around 220°C to 240°C․ TPU, being more flexible, works best at lower temperatures, usually between 200°C to 215°C․ ABS, known for its high thermal stability, often requires a heated bed and higher nozzle temperatures, around 220°C to 240°C․ Proper temperature calibration ensures smooth extrusion and adhesion without causing filament degradation or warping․ Adjusting these settings based on the specific filament type and printer model is essential for achieving optimal print quality and minimizing common printing issues․

4․2 Speed and Layer Height Recommendations

Printing speed and layer height significantly impact print quality and durability․ For most filaments, a print speed of 30-50 mm/s is recommended, with slower speeds enhancing precision․ Layer heights typically range from 0․2 mm for detailed prints to 0․3 mm for faster results․ PLA and PETG generally perform well at moderate speeds, while TPU may require slower settings due to its flexibility․ ABS, being more prone to warping, benefits from slightly reduced speeds and higher layer heights․ Balancing these settings ensures optimal adhesion, surface finish, and print stability, tailored to the specific filament and desired outcome․

4․3 Bed Adhesion Techniques for Different Materials

Ensuring proper bed adhesion is critical for successful 3D printing․ For materials like PLA and PETG, applying a thin layer of PVA glue or using a PVA glue stick enhances adhesion․ ABS benefits from a heated bed and boron carbide glass surfaces․ TPU and flexible filaments often require a textured PEI sheet or a direct drive extruder for better grip․ Cleaning the bed regularly and ensuring it’s level prevents adhesion issues․ Using adhesion sheets or boron carbide glass beds can also improve results for specific filaments, ensuring the first layer adheres properly and reduces the risk of warping or delamination during printing․

Troubleshooting Common Filament-Related Issues

Common filament issues include poor adhesion, stringing, and oozing․ Adjusting temperatures, ensuring proper bed leveling, and using appropriate retraction settings can resolve these problems effectively․

5․1 Dealing with Poor Layer Adhesion

Poor layer adhesion is a common issue in 3D printing, leading to weak bonds between layers․ This can cause prints to fail or detach during the printing process․ To address this, ensure the print bed is level and clean․ Using adhesion aids like PVA glue stick or liquid can significantly improve first-layer adhesion․ Adjusting the bed temperature to the recommended level for the specific filament type also plays a crucial role․ Increasing the flow rate slightly or lowering the print speed can help layers bond better․ Proper bed preparation and material settings are key to achieving strong layer adhesion․

5․2 Resolving Stringing and Oozing Problems

Stringing and oozing are common issues in 3D printing, caused by excess filament being deposited between layers or leaking from the extruder․ To resolve these, lower the nozzle temperature slightly to prevent overheating the filament․ Adjusting retraction settings is crucial—enable retraction, set an appropriate distance, and ensure the retraction speed is optimal․ Using a higher-quality nozzle, like one with a hardened steel tip, can also minimize oozing․ Additionally, ensure the extruder is properly calibrated and consider increasing the Z-offset to reduce oozing during travel moves․ Regularly cleaning the nozzle and maintaining consistent filament moisture levels further helps in reducing these issues effectively․